From structural steel to precision welding, your skills hold everything together – literally.

Whether you’re working on large-scale construction, manufacturing, or repair projects, employers need welders who can deliver accuracy and efficiency.

But before you can get to work on your next project, you need to forge something else – an outstanding CV. This guide and its 3 Welder CV examples will help you land your next welding role.

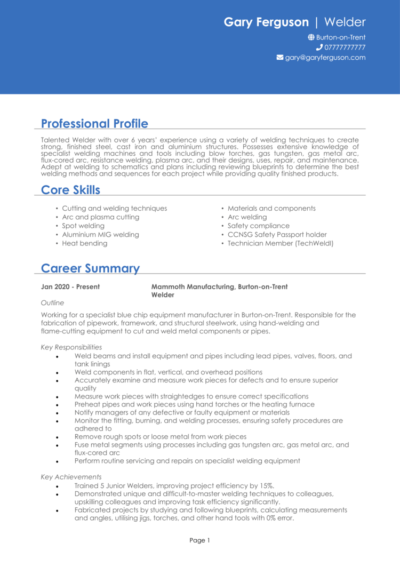

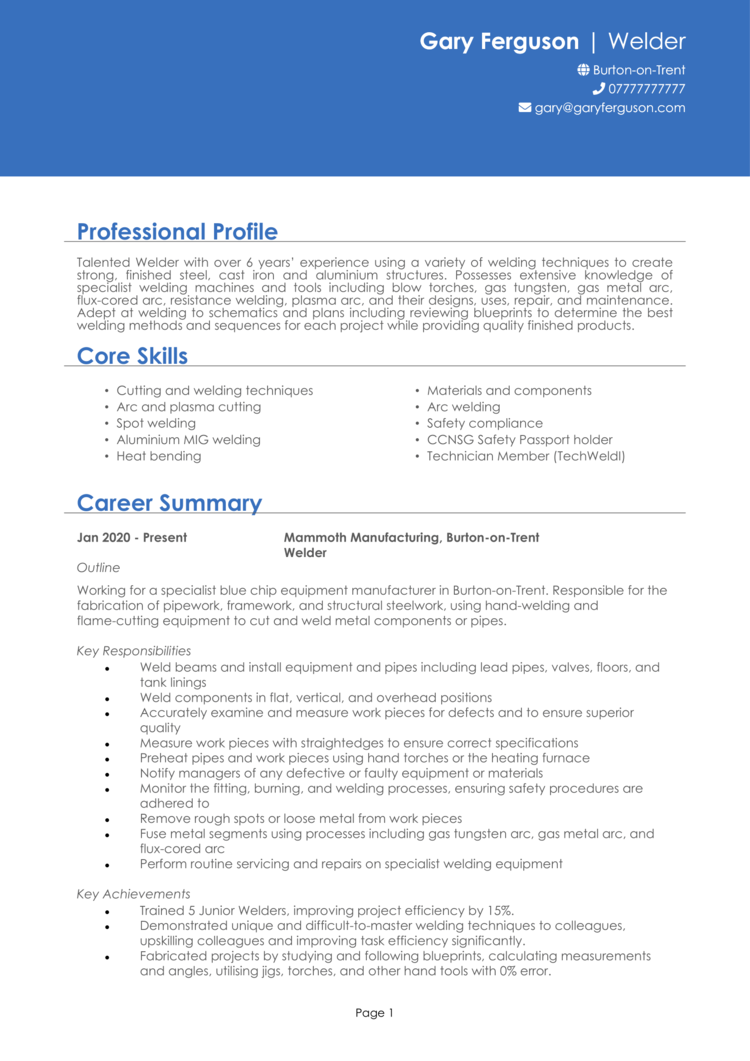

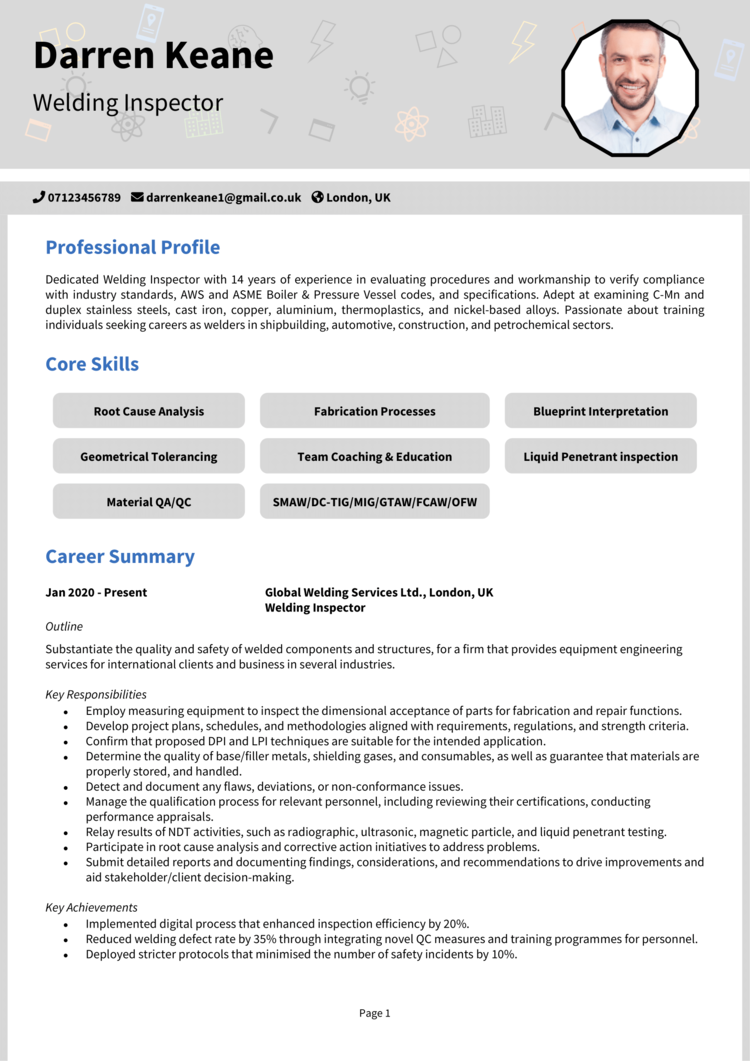

Welder CV

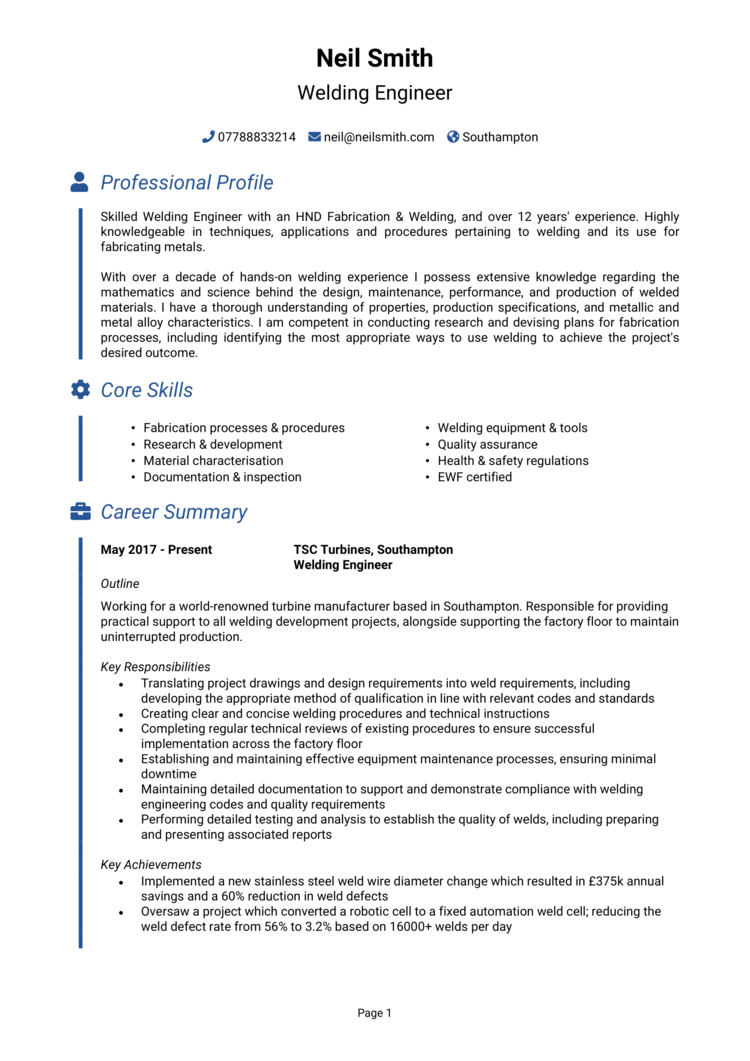

Welding Engineer CV

Welding Inspector CV

How to write your Welder CV

Discover how to craft a winning Welder CV that lands interviews with this simple step-by-step guide.

Welding is a profession where precision matters, and your CV should reflect the same level of attention to detail. If key skills and qualifications aren’t easy to find, hiring managers won’t take the time to search for them.

This guide will help you with writing a CV that displays your experience, certifications, and technical knowledge. Whether you specialise in construction or repair work, you’ll learn how to create a strong application that gets results.

How should you structure and format a Welder CV?

A well-organised and presentable CV structure ensures recruiters can quickly find your qualifications, experience, and technical skills without unnecessary distractions. Following these tips will ensure you avoid making mistakes that overshadow your impressive expertise.

Here’s the layout to follow:

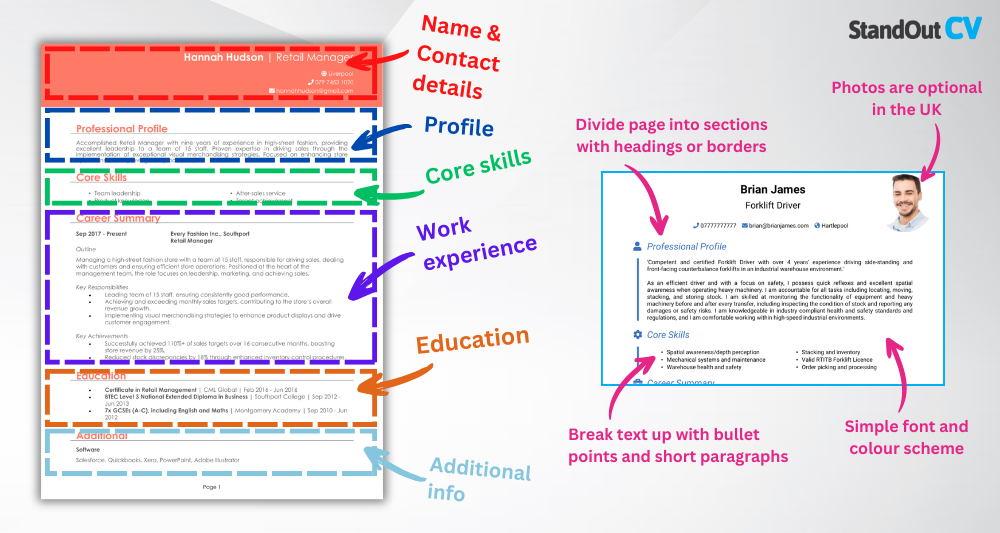

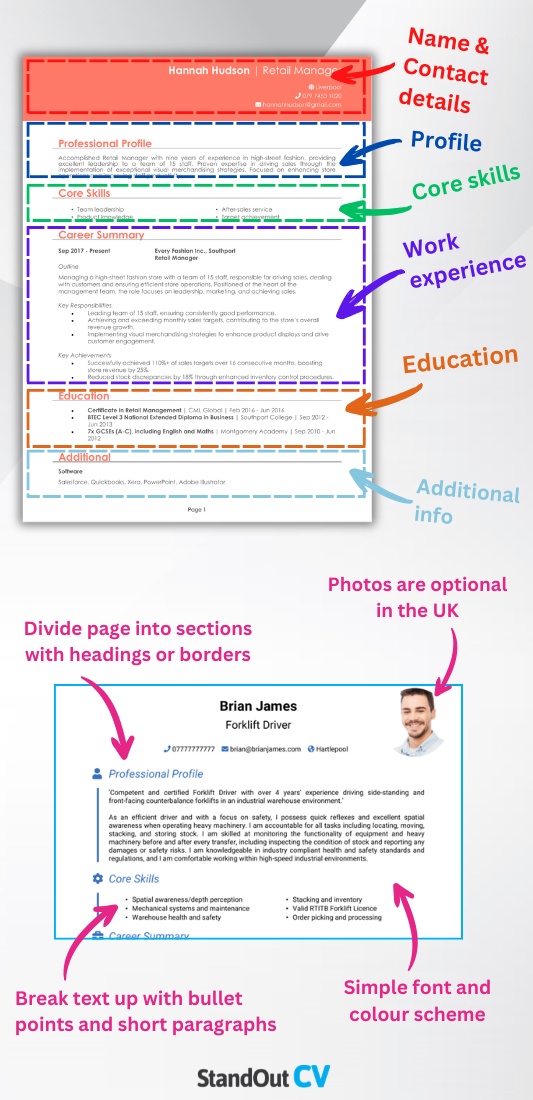

- Name and contact details – Place your name and personal details prominently at the top of your CV for quick access. Adding a picture of yourself is up to you.

- Profile – Open with a compelling overview of your skills, experience, and career goals.

- Core skills – Briefly highlight those qualities which make you the best candidate, such as MIG, TIG, or arc welding, blueprint reading, or metal fabrication.

- Work experience – Provide a detailed breakdown of your work history, starting with the most recent job first.

- Education – List your qualifications, including degrees and relevant certifications, in reverse chronological order.

- Additional info – Optionally, include professional memberships, relevant hobbies and interests, and awards.

A cluttered CV format is as inefficient as a messy welding station. Make use of bullet points for clarity, divide sections with clear headings, and stick to a professional, easy-to-read font. Keep it the right length – no longer than two pages – to ensure it’s sharp and focused.

Writing a Welder CV profile

Your CV profile is your chance to introduce yourself as a skilled and reliable welder. It should quickly highlight what makes you stand out from other candidates, outlining your key welding expertise and work ethic. A good profile is like a strong root weld – it holds everything else together.

Welder CV profile examples

Profile 1

Skilled Welder with four years of experience in MIG, TIG, and arc welding for industrial and construction projects. Proficient in reading blueprints, fabricating metal structures, and performing quality inspections. Adept at working with stainless steel, aluminium, and carbon steel. Committed to maintaining high safety standards and precision in all welding tasks.

Profile 2

Experienced Welder with three years of expertise in structural welding, pipefitting, and fabrication. Skilled in using plasma cutters, grinders, and welding machines to produce durable and high-quality metalwork. Adept at working in fast-paced environments, ensuring strong welds and compliance with industry standards. Dedicated to improving efficiency and reducing material waste.

Profile 3

Certified Welder with over six years of experience in heavy industry and automotive manufacturing. Specialises in robotic welding, structural repairs, and metal fabrication. Proficient in quality assurance procedures, non-destructive testing, and working with complex welding specifications. Passionate about precision craftsmanship and delivering long-lasting welds.

Details to put in your Welder CV profile

Here’s what to include:

- Welding specialisation – Whether you specialise in MIG, TIG, Stick, or Flux-Core welding, make it clear.

- Industry experience – Mention whether you’ve worked in construction, shipbuilding, automotive, or fabrication.

- Blueprint reading and technical skills – Employers value welders who can interpret designs and execute precise welds.

- Safety and compliance knowledge – Showcase your training in workplace safety, PPE use, and compliance with industry regulations.

- Attention to detail and efficiency – Highlight your ability to produce clean, strong welds while meeting deadlines.

Writing an effective core skills section

A welder’s skills go beyond just using a torch – employers look for professionals who can work efficiently, follow blueprints, and maintain high safety standards. Your CV skills section should read like a checklist of everything an employer is looking for in a welder.

Tailor your skills list to the specific job. If you’re working in structural welding, mention your ability to work with thick steel. If you’re in precision welding, highlight your finesse and attention to detail.

This section helps employers quickly assess whether you have the right skills for their specific welding projects.

The top skills to highlight in your Welder CV

- MIG, TIG, and Stick Welding – Mastering multiple welding techniques to work with different metals and applications.

- Blueprint and Technical Drawing Interpretation – Reading and understanding schematics, blueprints, and welding symbols to ensure precision.

- Metal Fabrication – Cutting, shaping, and assembling metal structures using welding and fabrication tools.

- Welding Safety and Compliance – Following workplace safety regulations, including PPE use, fire prevention, and ventilation requirements.

- Material Selection and Preparation – Identifying appropriate metals, cleaning surfaces, and preparing materials for welding.

- Quality Control and Inspection – Checking welds for strength, defects, and compliance with industry standards.

- Arc Welding and Plasma Cutting – Using arc welding and plasma cutters for precision cutting and joining of metals.

- Structural and Pipe Welding – Constructing and repairing steel structures, pipelines, and heavy machinery components.

- Welding Equipment Maintenance – Inspecting, troubleshooting, and maintaining welding machines and tools for optimal performance.

- Heat Treatment and Metal Hardening – Applying post-weld heat treatment to improve durability and structural integrity.

Showcasing your work experience

Your work experience should demonstrate more than just time on the job – it should prove your ability to produce high-quality welds, work efficiently, and contribute to projects successfully.

In reverse chronological order, focus on key responsibilities like reading blueprints, setting up welding equipment, and inspecting welds for defects. If you’ve worked with different metals or in high-pressure environments, highlight that experience.

If you’re newer to the field, include apprenticeships, trade school projects, or hands-on training that showcase your welding abilities.

Writing job descriptions for past roles

- Outline – Describe the company, the type of projects handled, and your role.

- Responsibilities – List key tasks, such as welding different metals, reading blueprints, or operating fabrication equipment. Use action words like “welded,” “fabricated,” and “inspected.”

- Achievements – Highlight improvements you contributed to, such as increasing welding efficiency, reducing defects, or completing projects ahead of schedule.

How to present past roles for Welders

Welder | Ironclad Engineering

Outline

Working within a leading steel fabrication company, performed high-precision welding for structural and industrial projects.

Responsibilities

- Read and interpreted blueprints to complete custom metal fabrications.

- Performed MIG and TIG welding on stainless steel and aluminium components.

- Conducted quality inspections to ensure weld integrity and compliance with safety regulations.

- Used cutting tools and grinders to shape and finish welded materials.

- Collaborated with engineers and supervisors to improve welding processes.

Achievements

- Reduced material waste by 15 percent through improved welding efficiency.

- Achieved a 98 percent first-pass inspection rate by ensuring precision and adherence to standards.

- Trained two apprentices in advanced welding techniques, improving team productivity.

Fabricator | Titan Metalworks

Outline

Provided welding and fabrication services for a high-volume manufacturing plant, ensuring durability and precision in metalwork.

Responsibilities

- Assembled and welded steel frames, beams, and brackets for construction projects.

- Used arc welding and gas welding techniques to produce high-strength joins.

- Repaired and modified existing metal structures, ensuring compliance with engineering standards.

- Followed detailed technical drawings and specifications for welding projects.

- Maintained welding equipment and conducted regular safety checks.

Achievements

- Completed over 500 high-quality welded assemblies with a 99 percent accuracy rate.

- Implemented a new welding process that increased productivity by 20 percent.

- Recognised for maintaining excellent safety records and adherence to workplace protocols.

Pipe Welder | Forge Solutions

Outline

Working within an industrial manufacturing firm, performed pipe welding and repair work for high-pressure systems.

Responsibilities

- Executed precision pipe welding for oil, gas, and water pipelines using TIG and stick welding techniques.

- Conducted non-destructive testing (NDT) to ensure the integrity of welded joints.

- Worked with high-temperature and high-pressure piping systems, following strict safety protocols.

- Fabricated and installed custom piping systems according to blueprints and schematics.

- Assisted in troubleshooting and repairing defective welds to prevent leaks and system failures.

Achievements

- Reduced repair time on faulty welds by 25 percent through improved inspection techniques.

- Certified in advanced pipe welding, improving project approval rates by 30 percent.

- Recognised for excellent workmanship and adherence to industrial safety standards.

Highlighting your education

Welding is a hands-on trade, but certifications and formal training still boost your CV by proving your expertise. Employers often look for recognised education and qualifications that ensure you meet industry standards.

List your relevant certifications and training, including welding school programs, on-the-job apprenticeships, and safety courses. If you’ve completed additional training in areas like non-destructive testing (NDT) or CNC machining, include those as well.

The best qualifications to boost a Welder CV

- AWS Certified Welder (CW) – A widely recognised certification proving welding competency.

- City & Guilds Level 2/3 Welding & Fabrication – Common in the UK for professional welding qualifications.

- NVQ Level 3 in Welding & Fabrication – Demonstrates advanced welding expertise and practical experience.

- OSHA Safety Certification – Essential for welders working in industrial or construction settings.

- CSCS Card (for UK welders in construction) – Ensures compliance with health and safety regulations.