As a Machine Operator, you keep production lines running smoothly and safely. From maintaining equipment to managing precise manufacturing processes, your role demands reliability and technical know-how.

However, before you can step up to manage your next production floor, your CV needs to clearly demonstrate your expertise in operating machinery, handling maintenance, and ensuring safety standards. This guide (along with Machine Operator CV examples) will show you exactly how to highlight your practical skills, technical experience, and professionalism to secure your next role.

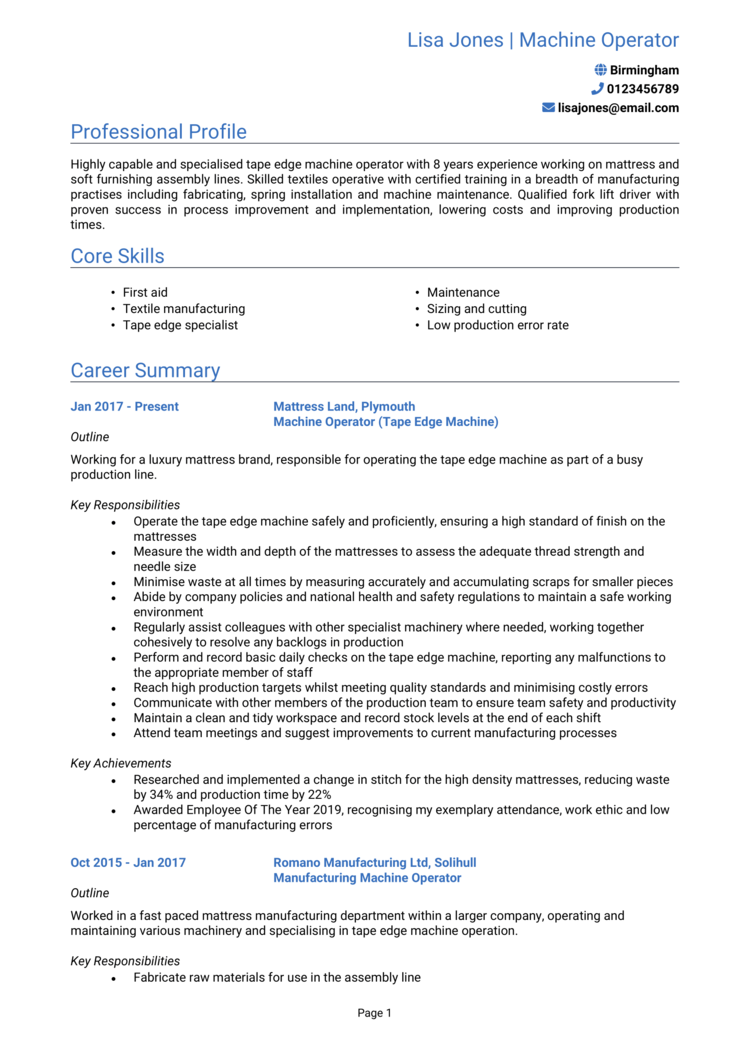

Machine Operator CV

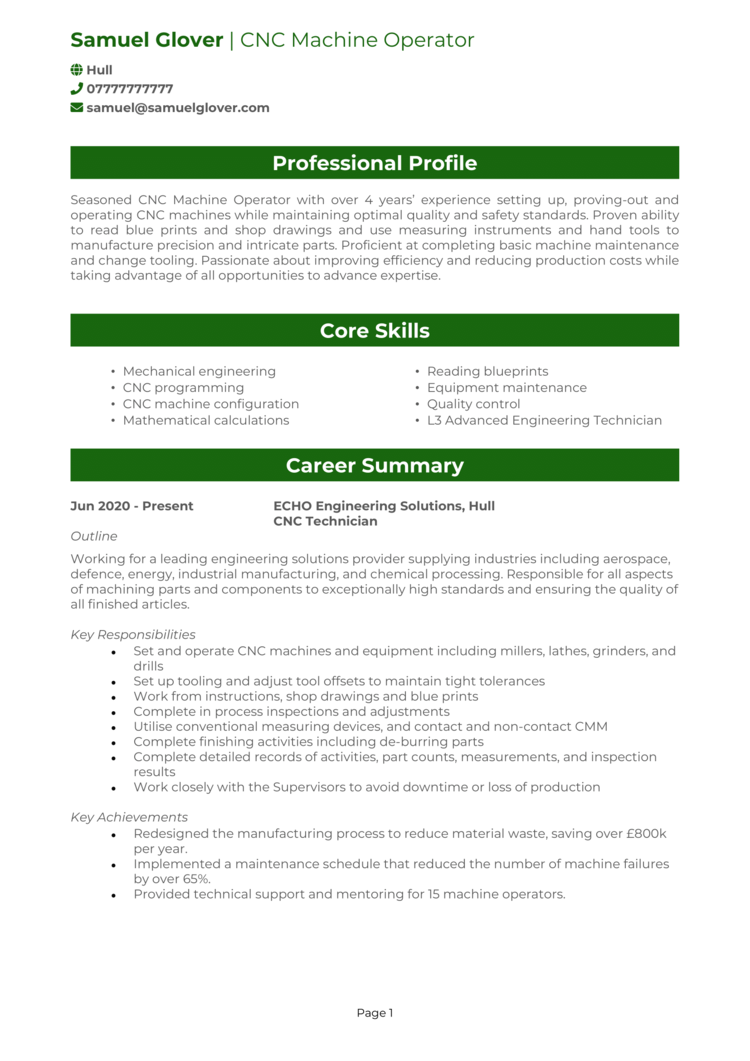

CNC Machine Operator CV

How to write your Machine Operator CV

Discover how to craft a winning Machine Operator CV that lands interviews with this simple step-by-step guide.

Your CV, much like the machinery you operate, needs to function flawlessly at first glance. Employers should quickly and clearly see your technical skills, reliability, and proven track record of keeping operations running efficiently.

This guide helps you write a CV so recruiters immediately recognise your value. Whether you specialise in manufacturing, packaging, or precision machining, your CV will demonstrate that you have the skills and experience they’re looking for – clearly, concisely, and convincingly.

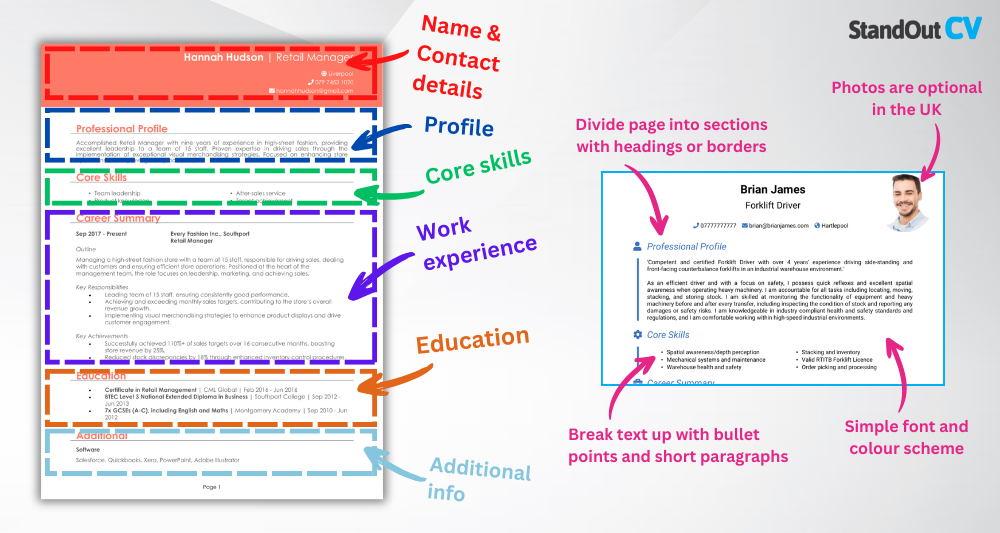

The correct structure and formatting for a Machine Operator CV

Recruiters prefer CVs that clearly display your qualifications, machine-specific skills, and work history without confusion. An organised layout makes it easy for employers to quickly pinpoint your relevant expertise.

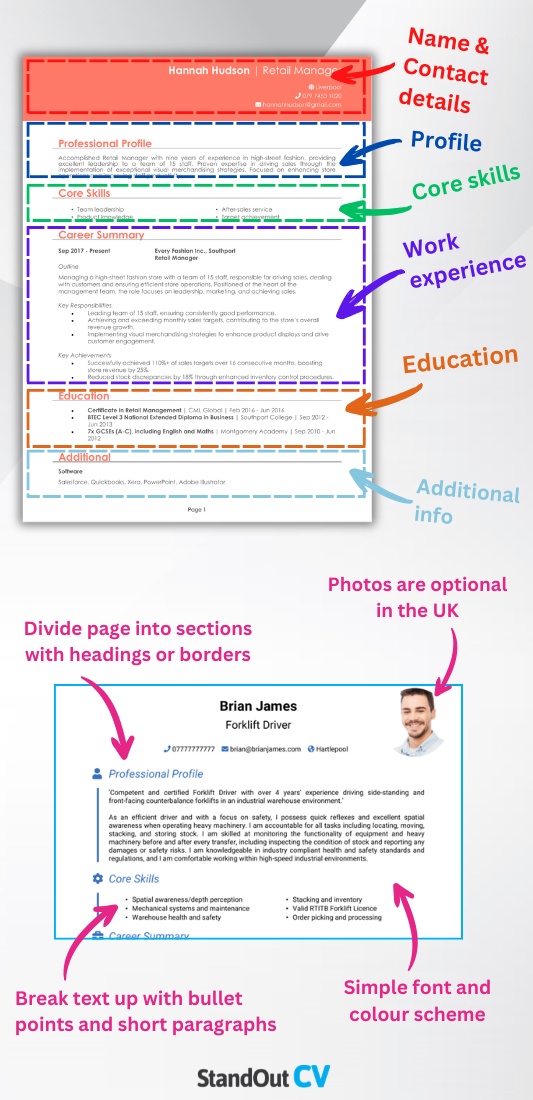

Follow this clear structure:

- Name and contact details – Present your personal details clearly at the top, making it easy for recruiters to contact you; a photo is entirely optional.

- Profile – Provide a concise summary clearly showing your experience, machinery expertise, and key skills in operating complex equipment.

- Core skills – Clearly highlight your most relevant technical abilities, such as equipment maintenance, quality assurance, or production efficiency.

- Work experience – Summarise your machinery operating roles, clearly emphasising your duties and achievements.

- Education & certifications – List your academic qualifications like a degree and relevant training clearly, especially if related to machinery, manufacturing, or safety.

- Additional info – Optionally include professional certifications, hobbies, and industry awards.

Your CV should be no longer than two pages in length – brief enough to stay engaging, but long enough to showcase your professional experience and skills effectively. Make full use of bullet points and borders to divide your sections, and stick with a readable, simple font for a nice and readable format .

CV profile for a Machine Operator

Your CV profile is your chance to clearly highlight your machine operating experience, technical skills, and reliability to employers in just a few lines. This is the first part any recruiter scans, so make sure you convey the benefits you’d bring if you were hired.

Machine Operator CV profile examples

Profile 1

Skilled Machine Operator with four years of experience in manufacturing and production environments. Proficient in operating CNC machines, assembly line equipment, and performing routine maintenance. Knowledgeable in safety protocols, quality control, and troubleshooting mechanical faults. Committed to maintaining efficient production workflows and ensuring product consistency.

Profile 2

Experienced Machine Operator with three years of hands-on experience working with industrial equipment in high-volume production facilities. Skilled in setting up machines, interpreting technical drawings, and monitoring output for quality standards. Strong attention to detail and a solid understanding of lean manufacturing principles.

Profile 3

Reliable Machine Operator with over five years of experience operating and maintaining automated machinery in fast-paced factory settings. Adept at machine calibration, performing quality checks, and adhering to health and safety guidelines. Known for minimising downtime and maintaining high production standards.

Details to put in your Machine Operator CV profile

Clearly include the following details:

- Machinery expertise – Specify your experience with types of machinery, such as CNC machines, manufacturing equipment, or assembly lines.

- Technical abilities – Clearly show your skills in operating, troubleshooting, and maintaining machinery.

- Safety knowledge – Emphasise your adherence to safety guidelines and compliance with manufacturing standards.

- Efficiency and productivity – Briefly highlight your capability in meeting production targets and improving efficiency.

- Career objectives – State the types of roles you seek, showing your enthusiasm and clarity about your career path.

How should you write a core skills section?

Clearly outline skills directly relevant to machine operation roles, such as equipment operation, preventative maintenance, fault diagnosis, quality control, and compliance with safety standards.

Adapt these skills specifically to match the job description you’re targeting. Be clear and concise; recruiters appreciate specificity over vague abilities.

Key skills for a Machine Operator CV

- Machine Setup and Calibration – Preparing machinery for operation by configuring settings, calibrating components, and ensuring readiness.

- Operation of Industrial Equipment – Running machines such as CNC tools, presses, or packaging equipment according to specifications.

- Quality Control and Inspection – Monitoring output for accuracy, consistency, and defects, using measuring tools and visual checks.

- Maintenance and Troubleshooting – Performing routine maintenance and identifying mechanical issues to minimise downtime.

- Production Reporting – Recording production data, downtime, and maintenance activities for operational tracking.

- Material Handling – Loading raw materials into machines and unloading finished products safely and efficiently.

- Safety and Compliance – Adhering to health, safety, and environmental regulations, including PPE and lockout/tagout procedures.

- Reading Technical Drawings and Instructions – Interpreting blueprints, manuals, or schematics to guide machine operations.

- Tool and Die Handling – Replacing and adjusting tools and dies to accommodate different products or production stages.

- Efficiency and Time Management – Maintaining consistent production rates while minimising waste and downtime.

Writing about your work experience

Recruiters want clear evidence of your capabilities in machinery operation and maintenance. Instead of merely listing jobs, showcase examples where you’ve increased productivity, maintained high safety standards, or significantly improved machine performance.

Begin with your most recent or most relevant work experience, emphasising the specific machines you’ve worked with, your responsibilities, and practical achievements. For those newer to the industry, clearly detail relevant apprenticeships, training positions, or placements that demonstrate essential machine operation skills.

Formatting your job history for your CV

- Outline – Clearly describe the company, type of machinery operated, and your specific role.

- Responsibilities – Clearly list your tasks, such as setting up machines, maintaining equipment, and monitoring quality. Use clear action verbs like “operated,” “maintained,” and “inspected.”

- Achievements – Emphasise measurable results like improved machine efficiency, reduced downtime, or better safety compliance. A great tip is to sprinkle numbers throughout your CV wherever possible.

Work experience samples for Machine Operators

Machine Operator | Rivex Manufacturing Ltd

Outline

Operated automated machinery for a national automotive parts manufacturer, ensuring efficient production and quality assurance.

Responsibilities

- Set up and operated CNC machines according to daily production schedules.

- Monitored machine output and inspected finished parts for defects and accuracy.

- Performed minor machine maintenance and reported faults to technicians.

- Recorded production data and reported any discrepancies to supervisors.

- Adhered to safety regulations and contributed to a clean and hazard-free work environment.

Achievements

- Reduced machine downtime by 20 percent by identifying and reporting mechanical issues early.

- Consistently met daily production targets with a 98 percent quality pass rate.

- Received employee recognition for maintaining top performance during high-demand periods.

Machine Operator | Northmoor Plastics

Outline

Operated injection moulding equipment for a large-scale plastics manufacturer, supporting continuous production and product consistency.

Responsibilities

- Prepared raw materials and loaded them into machinery according to batch requirements.

- Adjusted machine settings to meet specific product specifications.

- Conducted visual and dimensional inspections of plastic components during production.

- Maintained logs of production output, machine run-time, and quality issues.

- Followed standard operating procedures to meet safety and efficiency goals.

Achievements

- Improved product consistency by implementing real-time monitoring techniques.

- Helped train two new operators on moulding equipment and safety procedures.

- Maintained a 100 percent attendance record over 12 months of shift work.

Machine Operator | Brightedge Steelworks

Outline

Operated industrial saws and fabrication equipment for a regional steel supplier, contributing to the preparation of materials for construction and infrastructure projects.

Responsibilities

- Interpreted technical drawings to cut and shape metal components to precise measurements.

- Maintained and calibrated machinery to ensure optimal performance.

- Inspected finished steel parts for imperfections and ensured adherence to tolerance limits.

- Collaborated with warehouse staff to prepare materials for dispatch.

- Completed daily maintenance checklists and complied with workplace safety policies.

Achievements

- Reduced material waste by 15 percent through precise machine setup and careful handling.

- Played a key role in meeting tight deadlines for a major infrastructure contract.

- Recognised for consistently producing high-quality work with minimal supervision.

How to write your education section

Clearly present relevant training or qualifications, such as diplomas in manufacturing, mechanical engineering, or certifications like City & Guilds qualifications. While these are essential, your education section should be brief compared to your experience.

Include any additional training relevant to machinery operation, such as health and safety certifications, first aid, forklift licenses, or specialised equipment training.

Recommended qualifications for Machine Operators

- NVQ Level 2 or 3 in Performing Manufacturing Operations – Highly regarded qualification demonstrating practical machinery skills.

- City & Guilds Certificate in Engineering – Clearly shows technical knowledge relevant to machine operations.

- IOSH Managing Safely – Demonstrates competence in maintaining high safety standards in manufacturing settings.

- CPCS or NPORS Certification (Forklift or Plant Machinery) – Valuable qualifications for operating industrial equipment.

- Diploma in Mechanical Engineering (Level 2/3) – Strong foundation demonstrating practical engineering and machinery operation skills.